WHAT IS PYRO-PROPELLING INDUSTRY?

Pyro-Propelling System, is the product to use Pyrotechnic or High Pressure Gas Storage to provide Propelling Energy or Fillant. Normally, the products involved in automotive industry are inflators, hoodlifters, pyrofuse and igniter.

Inflators are the units offering gas for Airbag during deployment. By the working type, inflator could be categorized as pyrotechnic type, hybrid type and cold gas type.

The pyrotechnic inflators are transfering solid to gas by chemical reaction. Cold gas inflators are fully mechanical, using high pressure storage.

As inflators are safety relative parts, and one-time function, it cannot use result testing. The manufacturing process control and inflator storage would be key for the inflator prouction.

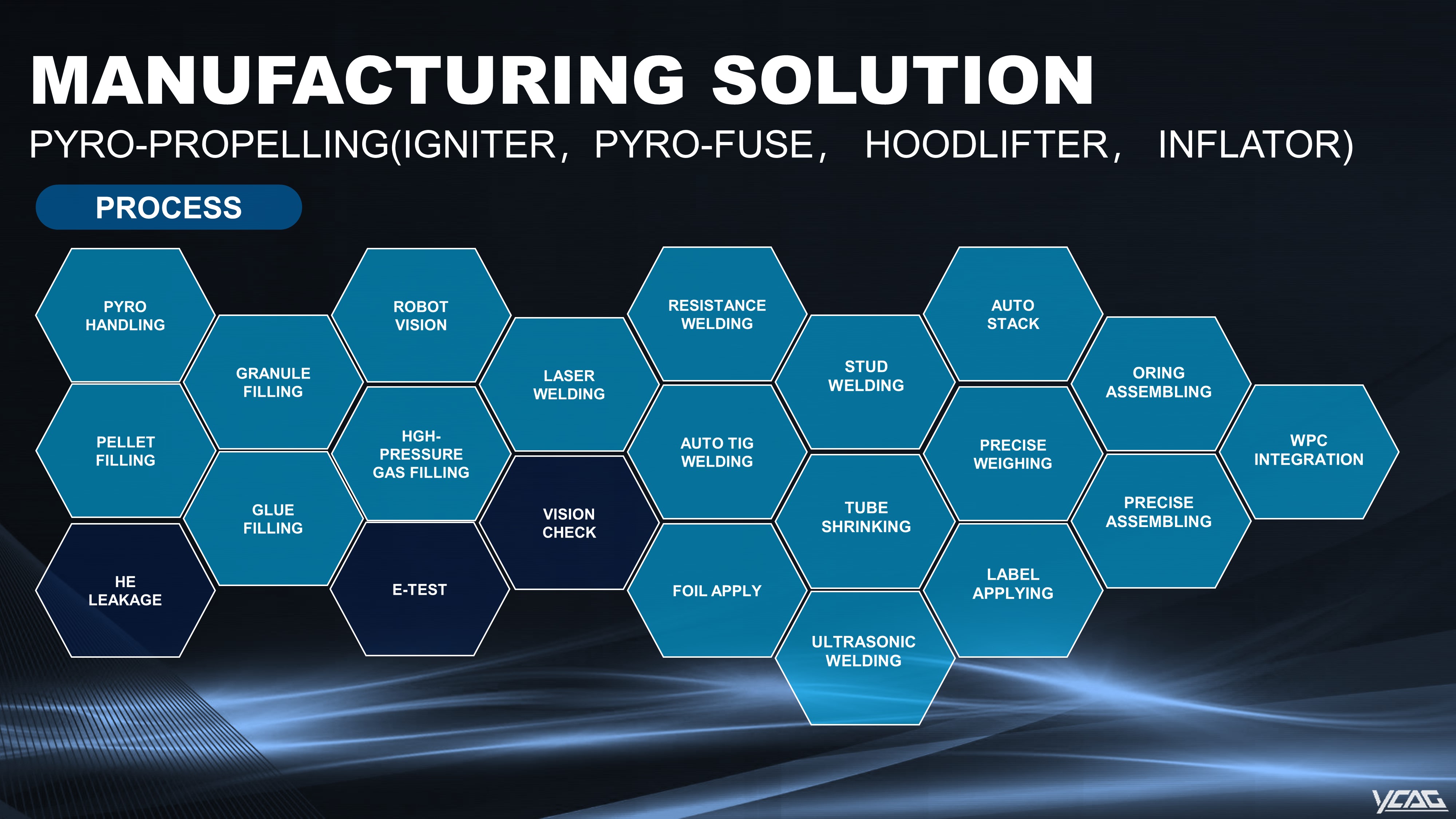

The process used in inflators' production are Crimping, Laser Welding, Precise Pressing, Propellant filling, label applying, friction welding, high pressure gas filling, resistance welding, Helium Leakage Check, Eletrical Characteristics Testing

HOW IS AUTOMATION IN PYRO-PROPELLING INDUSTRY?

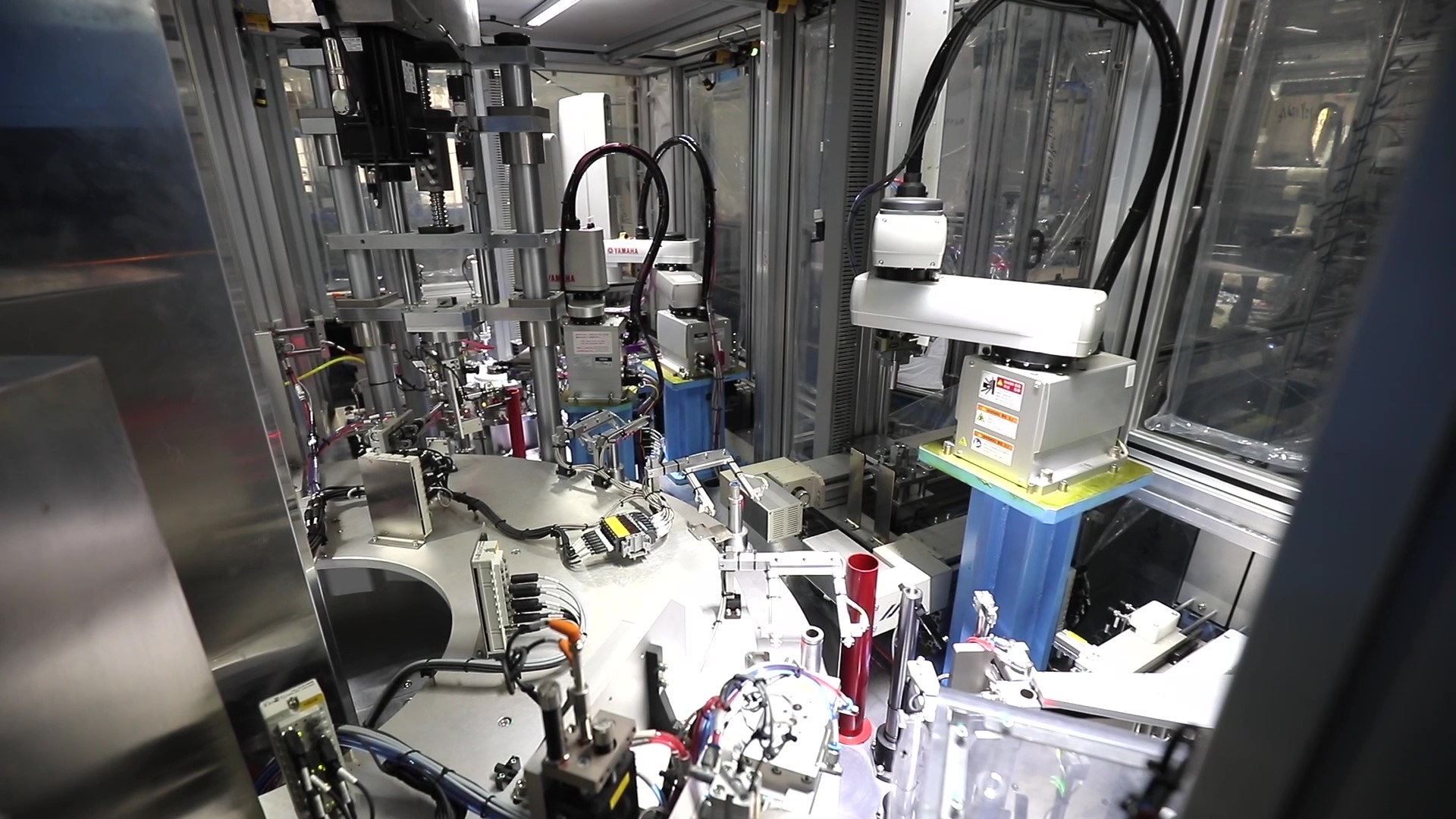

ROBIC MATERIAL HANDLING:

No operator involved manufacturing process, all the motions fulfilled by the mechanical structure and robot, with work piece carrier or rotary table. The material supplied with bowl feeder or part pallets

HIGH QUALITY CONTROL:

Every step of assembling process has process control tracking, the raw material before assembling into product, has critical features checking.

EXPLOSION PROOF

As the propellant are pyrotechnic parts, the equipment need to be built with explosion proof design.

APPLICATION OF INFLATOR INDUSTRY

Inflator Assembly

PRODUCT: Pyrotechnic Inflator

CYCLE TIME: 8 Seconds

LEAD TIME: 24 Weeks

PROCESS :

- Riveting : Rivet pressed forming for sheet connection

- Pellets Filling : Fill pellets using vibration system to specified container

- Precise Assembling : Press-fit with orientation and location requirement, Force & Way control

- Robic Material Handling : Material load / unload with robot

- Laser Welding: 360 Degree Laser welding for metal parts

- Stud Welding: Electric Arc Welding stud onto tube

- Tube Shrinking : Shrink Tube inner dimension for structurer construction

- Foil Applying: Apply foil on to specified surface, flat, inner circle, etc...

- Helium Leakage Check : Leakage check system, use Helium Leakage detector integration

- Function Test : Electric Charasteristics Test of Inflators

- Vision Check : Vision identification and judgement for mistake proofing, process result identification, measurement.

PROCESSES