WHAT IS STEERING WHEEL INDUSTRY?

Steering Wheels are more manual operation related product. From foaming, leather warpping to final Assembling and Testing. Manual operation is the major assembling way. The steering wheel is customized, all the parts of steering wheel are customized.

Processes involved in steering wheel assembling are, screwing, glue dispensing, wire adjustment, Testing

HOW IS THE AUTOMATION IN STEERING WHEEL INDUSTRY?

STANDARDING MANUFACTURING UNIT

As the high customization requirements, the full automation in Steering Wheel manufacturing will be not cost effective. The only way is to break the production line physical link, instead, we provide the solution of standard manufactring island, concentrating the same process in same area with duplicated standard units. Manufacturing material flow could be handled with either manual, conveyor or even the flex link (AGV...)

QUICK DOCK MANUFACTURING

To satisfy the high frequency change over requirement, the Fixtures/Jigs are designed with the quick dock elements, allowing the production could quick switch due to the production scheduling

MAN - MACHINE COOPERATION

Due to the design of steering wheel, the manual process is always integrated into the automatic process. Manual-Machine cooperation design will be the key points for customers.

APPLICATION OF STEERING WHEEL INDUSTRY

Steering Wheel Assembly

PRODUCT: Round/Half-Round Type Steering Wheel Assembling

CYCLE TIME: 45 Seconds

LEAD TIME: 20 Weeks

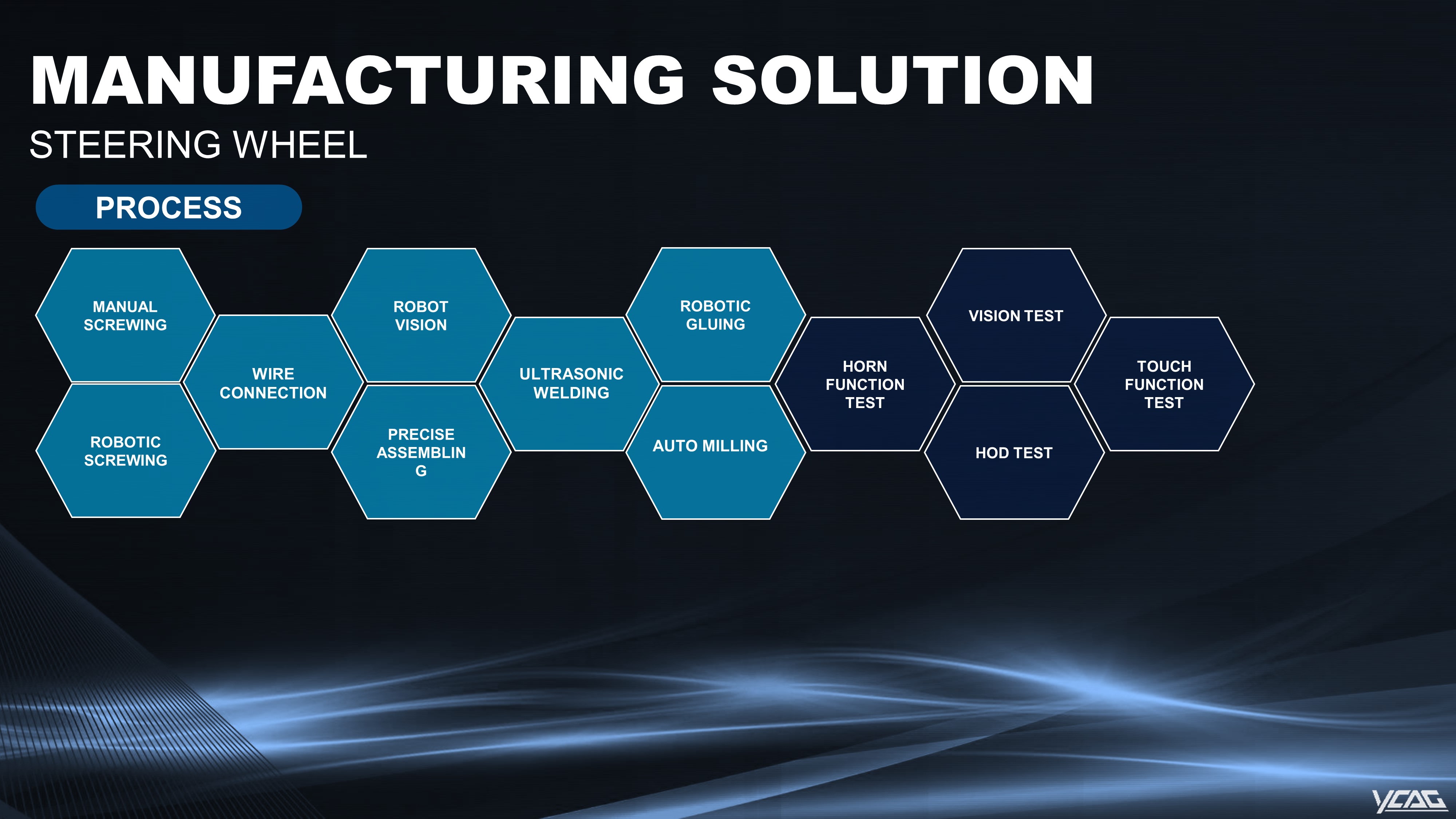

PROCESS :

- Screwing : Torque & Way control , automatic/manual feeding

- Manual Adjustment : Corrent components identification, manual assembling gap check

- Robotic Screwing : Robot holding screw with automatic screw feeding system, screw driving with angle is available.

- Function Testing : HOD (Hands On/Off) Detection, Horn connectivity, Switch Function Testing, Touch feedback, Illumination & etc.

PROCESSES